If you ask any construction project executive what keeps them awake at night, ductwork isn’t the obvious answer; until a beam clash halts installation, fabrication has to be redone, the ceiling cavity doesn’t accommodate the main trunk, or airflow tests fail during commissioning.

Recent research backs up what contractors have been shouting for years. A 2025 Buildings study found that design errors and communication lapses sit at the top of the rework food chain, especially on projects packed with dense HVAC, plumbing, fire, and electrical systems. In other words, if the team isn’t aligned early, you’ll pay for it later, usually in labor hours, change orders, and some hurt reputation.

For HVAC duct shop drawings, this all leads to one simple insight. The earlier the clarity, the cleaner the install. Detailed, accurate duct layouts don’t just help your fabricator; they’re one of the most effective risk-control tools a project manager can have.

What are HVAC Duct Shop Drawings?

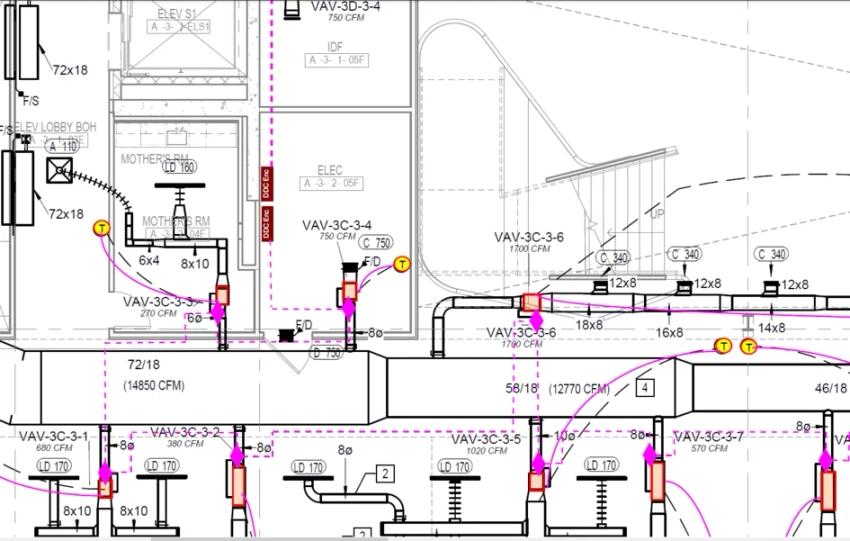

HVAC shop drawings are detailed technical drawings providing an extensive depiction of HVAC systems within a building. The drawings provide information on how the duct has to be routed, and the location of duct accessories like duct fire dampers, VAV boxes, Volume control dampers, and others.

These blueprints are developed meticulously to guide the contractors, installers, and fabricators about HVAC installation in a project with utmost efficiency and accuracy. Engineers prepare these drawings for contractors and their teams to provide an exact idea about the construction work.

What Services are Included in HVAC Duct Shop Drawings

- HVAC Shop Drawings Services

- HVAC Duct Design

- Duct Sections and Levels

- HVAC Duct Fabrication Drawing

- HVAC Duct Layout Drawing

- Details of Air Handling Unit

- HVAC Clash Detection & Resolution

- Mechanical Room BIM Modeling

- Fire Dampers, Grilles, Coils, and Fans Modeling

- Humidifiers and Dehumidifiers Modeling

- MEP Installation CAD Drawings

Why HVAC Duct Shop Drawings Matter More Than Ever

In today’s MEP projects, ductwork isn’t just about moving air; it’s about navigating tight spaces, tighter schedules, and zero tolerance for surprises.

Cost Control in High-Volume MEP Work

MEP accounts for 30–60% of total project cost in healthcare, data centers, airports, and large commercial projects.

Within this, duct fabrication drawings are disproportionately sensitive because:

- The drawings demand early routing in ceiling zones

- Ductwork shop drawings compete with electrical conduits, fire lines & plumbing stacks

- They drive static pressure, fan sizing & operational energy

- MEP HVAC shop drawings directly influence space planning and architectural design

Shorter Schedules, Higher Risks

Design–build and fast-track delivery, compress MEP coordination windows.

When duct fabrication drawings are late or incomplete:

- RFIs spike

- Fabrication cycles slip

- Site teams resort to field modifications

- Commissioning becomes unpredictable

Impact on System Performance

Duct leakage alone can reduce HVAC efficiency by 20%. Most leakage originates not from on-site installation mistakes but from:

- Misaligned ducts caused by poor dimensional accuracy

- Wrong joints or fittings due to incomplete detailing

- Improper sealant or gasket selection tied to missing specifications

All are preventable when shop drawings are treated as engineering documents, not drafting artifacts.

Why Project Stakeholders Need to Prioritize Ductwork Shop Drawings

Different stakeholders experience the consequences differently.

Shop Drawings for Architects

Architects don’t size ducts, but they bear the consequences when:

- Ducts exceed ceiling space allowances

- Access doors interfere with aesthetics

- Return air paths conflict with lighting layouts

- Mechanical rooms are undersized

Architects benefit most from MEP HVAC shop drawings that provide realistic, spatially accurate layouts during early coordination, not after drywall framing.

MEP HVAC Shop Drawings for Mechanical Engineers

For engineers, duct fabrication drawings are the execution layer of their design intent.

They rely on shop drawings to validate:

- Correct duct gauges, reinforcement, and insulation thickness

- Accurate selection of fittings like radius elbows vs. mitered

- Compliance with pressure class

- Air balancing feasibility

- Damper accessibility

- Equipment-to-duct alignment

Engineers need shop drawings that retain mechanical logic, not just geometry.

Duct Shop Drawings for Mechanical Contractors & Fabricators

Shop drawings for HVAC contractors are the production and installation manual:

- Fabricators depend on the drawings for cut lengths, joint details, and transitions.

- Installers depend on MEP coordination shop drawings for hanger spacing, coordination clearances, and sequencing.

- Field supervisors rely on them to reduce rework, manage labor, and hit milestones.

When drawings are unclear, field improvisation begins, and that’s where risk explodes.

Benefits of HVAC Duct Shop Drawings

HVAC Duct shop drawings offer multiple benefits to the stakeholders and uplift the design and construction work quality. Here are a few of its benefits:

Streamlined Installations

HVAC Shop drawings provide a visual roadmap to the contractors and fabricators, enabling them to work with confidence and surety

They are aware of the exact locations of each element and the preferable interconnecting methods. The availability of drawings allows for a seamless and streamlined installation process.

Coordination and Collaboration

HVAC Shop drawings facilitate a smooth collaboration between different trades involved in a project. These drawings ensure seamless integration with other systems like electrical, plumbing, and mechanical.

The uninterrupted integration allows for a conflict-free construction, avoiding any clashes or defects.

Enhanced Accuracy

The scope of making choices based on probability or guesswork is eliminated with HVAC duct shop drawings. These drawings enlist precise dimensions, duct layouts, equipment specifications, pipe routing, and electrical connections.

The detailed and precise specifications ensure that every element fits flawlessly where it belongs and devise accurate onsite execution.

Cost and Time Savings

The accuracy and precision induced with HVAC drawings eliminate the need to redesign or rework. The projects progress seamlessly on-site within budget constraints and required timelines.

The fabricators can efficiently generate HVAC components using the shop drawings, eliminating material wastage and costly errors.

What High-Quality HVAC Duct Shop Drawings Must Include

Before we dive into the nuts and bolts, here’s the truth. High quality mechanical shop drawings for HVAC don’t start with software; they start with clarity, curiosity, and the discipline to get the fundamentals right.

System Requirements & Design Intent Extraction

- Required airflow (CFM/CMH) by zone

- Static pressure limitations

- Pressure class & duct construction class per SMACNA

- Velocity caps for different segments

- Equipment neck sizes and transition rules

- Smoke control or fire-rated duct requirements

Errors at this step propagate through the entire project.

Duct Sizing & Pressure Loss Calculations

Modern shop drawings now integrate:

- Equal-friction method, optimized for uniform pressure loss

- Velocity reduction method for noise control

- Static regain method in large trunk systems

- ASHRAE-based friction charts

- CFD-informed velocity distribution for critical rooms

Decision-makers must ensure that duct sizing is not just “taken from design drawings” but recalculated based on actual routed lengths and fittings.

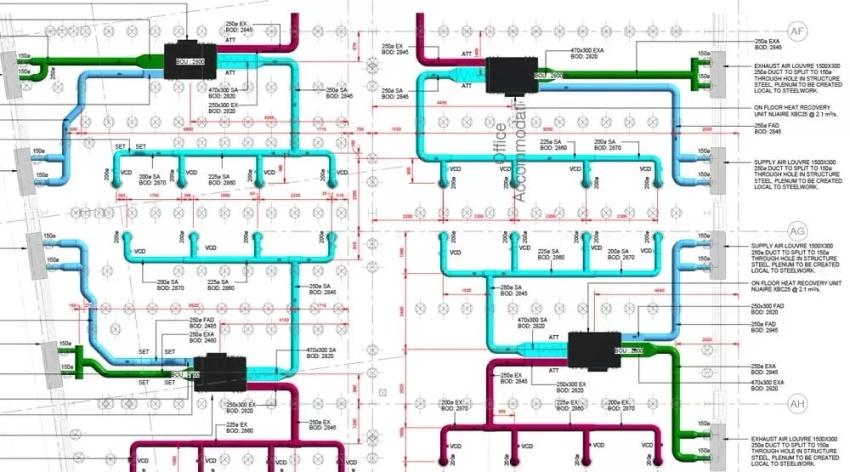

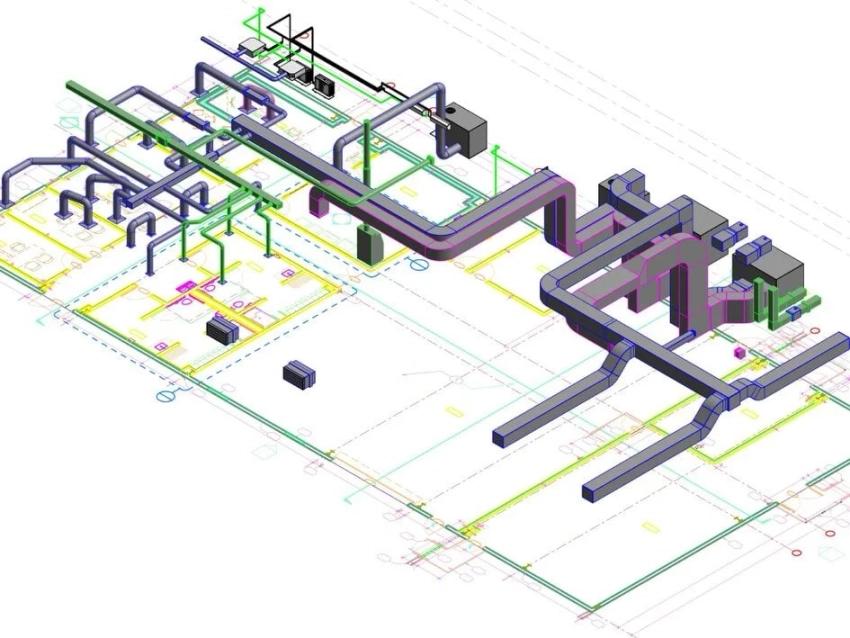

Spatial Coordination & Clash Avoidance

Accurate shop drawings depend on:

- Precise ceiling void Modeling

- Structural RCC/steel beam interference checks

- Equipment clearance envelopes

- Fire-stopping and code-driven separation

- HVAC Coordination with plumbing, FP, electrical, low-voltage, and architectural ceiling grids

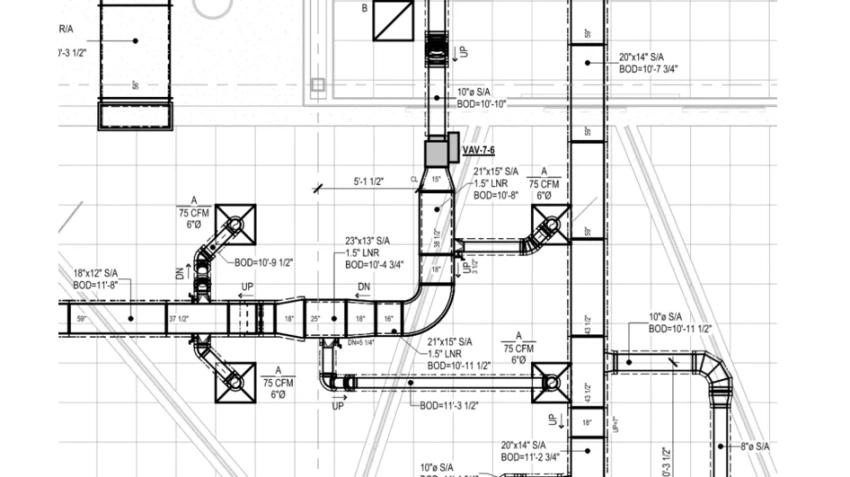

Fabrication-Ready Detailing, Such as Fittings, Joints, Reinforcement

Fabricators need:

- Seam type

- S-clip, TDC/TDF, angle joints

- Hanger rod spacing per SMACNA

- Access door placement for dampers & VAVs

- Turning vane specifications

- Radius vs. mitered elbow rules

- Transition geometry (conical vs. offset)

- Spiral vs. rectangular duct justification

- This is where installation productivity is either saved or lost.

Installation Logic & Sequencing

Quality shop drawings anticipate:

- Longest-route assemblies

- Hanger preloading

- Connection coordination with VAVs, AHUs, FCUs

- Duct risers sequencing

- Shaft clearances and shaft wall penetrations

These details directly affect site labour utilization — a major cost driver.

Risk & Quality Control: HVAC Duct Shop Drawing Mistakes That Detail Projects

Every MEP leader has a story about a minor drawing issue that ballooned into a scheduling nightmare. The truth is, most of these failures are not surprises; they’re patterns, and they tend to show up in the same places again and again.

Relying on design drawings as if they’re fabrication-ready

Design drawings are great for intent, but anyone who has built ductwork knows they rarely match the messy reality. They don’t account for insulation, flanges, or what the shop can actually fabricate. Those little gaps become big field headaches, extra labour, rework, and improvised fixes no one budgeted for.

Ceiling heights that shift while no one is looking

Ceiling cavities shrink due to lighting changes or architectural tweaks, but the duct routes don’t always get revisited. What fit on paper last month suddenly collides with a beam or sprinkler main. Without validating clearances at the shop-drawing stage, the conflict becomes the contractor’s problem and a costly one.

Incorrect pressure class or construction standards

Get the pressure class wrong and ducts either rattle themselves tired or become unnecessarily heavy and expensive. A quick early check on gauge and reinforcement saves everyone from avoidable headaches and blown budgets.

Damper and access placements that ignore real-world maintenance

Nothing frustrates field crews more than a fire damper tucked behind cable trays or above a fixed ceiling. Poorly placed dampers lead to cut ceilings, disputes, and inspection delays.

Missed code-driven details

Fire ratings, smoke paths, and seismic bracing are easy to overlook until the inspector shows up. By then, it’s chaos: ceilings opened, schedules slipping, budgets bruised. Catching these details early saves everyone pain.

Hence, every hour invested in better shop drawings for HVAC contractors saves days of firefighting later.

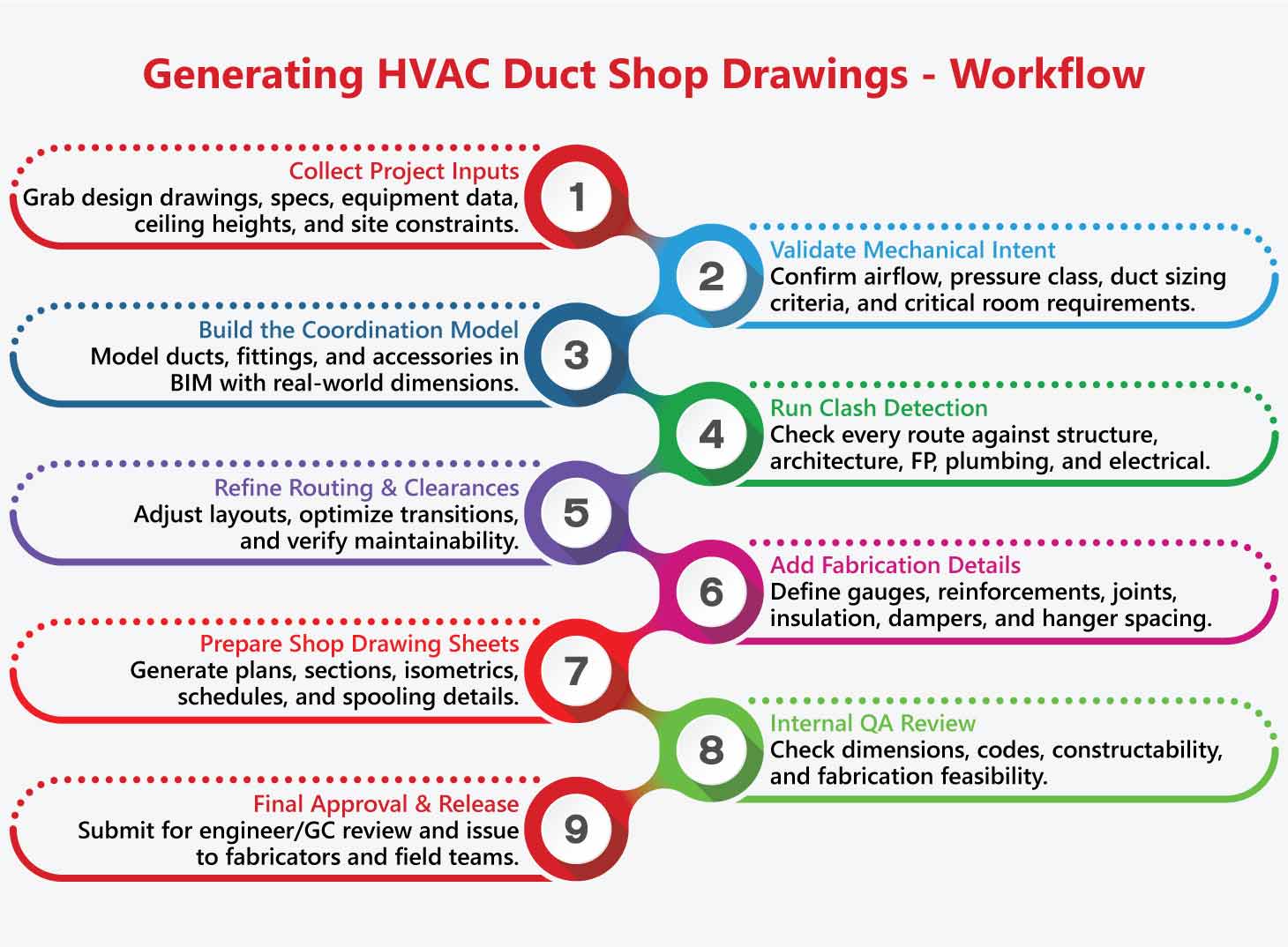

Key Steps of Generating HVAC Duct Shop Drawings

HVAC duct shop drawings play an essential role in the successful implementation of its systems. The drawings formulate a roadmap for the fabrication, installation, and coordination of ductwork within a building. The key steps for generating HVAC Duct shop drawings from inception to execution are:

Understanding Project Requirements

For HVAC duct shop drawings, it’s important to collect relevant information about every aspect of the project. The necessary information includes architectural drawings, structure drawings, mechanical specifications, equipment details, and any specific design considerations.

Design Team Collaboration

For drawing accuracy and precision, it is crucial to develop effective collaboration between the design team. Intense discussions between the team members to understand the spatial constraints, design intent, and requirements are significant to generate comprehensive drawings.

Proper coordination should be established with architects, mechanical engineers, and other stakeholders to ensure a better project understanding.

Accurate Layout and Measurement

Accuracy of measurements and layout is paramount for creating precise HVAC Duct shop drawings. The accurate building dimensions of the existing systems and the entire building can be documented with laser measuring devices and digital tools. These devices also capture any obstruction or hindrances that might impact the ductwork layout.

Conceptualizing Ductwork Layout

With project requirements and design specifications detailed, the ductwork layout can be conceptualized. Factors such as pressure drops, airflow requirements, accessibility, zoning, and equipment locations should be considered while conceptualizing the layout. The appropriate duct sizes, routing, and placement can be determined using industry standards and guidelines.

Developing Detailed Shop Drawings

After finalizing the layout of the HVAC duct, the next step is to develop detailed shop drawings. The 2D and 3D representations of the ductwork are generated using CAD software.

These drawings should include dimensions, duct sizes, insulation requirements, fitting details, and any important annotations. All the components should be properly labeled and numbered for easy identification during installation.

Coordinating with other Stakeholders

To ensure seamless integration of ductwork within the building and avoid clashes, effective coordination with other trades is significant.

The HVAC duct shop drawings should be shared and reviewed with structural, electrical, mechanical, and plumbing teams to identify any conflicts and rectify the situation by making required adjustments. Coordinated drawings encapsulating all necessary information can be developed by collaborating with all stakeholders.

Compliance with Codes and Standards

HVAC shop drawings should adhere to the local building codes, regulatory requirements, and industry standards. The drawings should include fire protection measures, accessibility considerations, and clearance guidelines.

The code consultants or third-party reviewers can be consulted, if necessary, to ensure adherence to codes and standards with their expertise.

Reviewing and Approvals

Before proceeding with installation, drawings should be thoroughly reviewed for accuracy, compliance, and completeness. The suggestions and approvals from the design team, project managers, and other stakeholders can help in identifying any potential issues, if any. To expedite the approval process, the inputs should be addressed promptly.

Fabrication and Installation Support

The fabrication team functions further according to approved HVAC shop drawings. Assist the team with clear and detailed instructions as per the drawings.

Timely addressing any query during the fabrication process can catalyze the fabrication process. Providing on-site support for the accurate implementation of the ductwork during the installation phase is a crucial measure to avoid issues and rework.

As-built Drawings and Documentation

A comprehensive documentation of final HVAC Duct Shop drawings along with revisions and approvals should be maintained by the Design team.

Any changes made during the time of construction should be updated in the drawings as the project progresses. The final as-built drawings should be documented upon project completion to have a record of the final installed ductwork.

Conclusion

HVAC duct shop drawings sit at the intersection of engineering intent, fabrication reality, and site execution. When done well, they compress schedules, prevent rework, preserve margins, and create duct systems that perform reliably throughout a building’s life cycle.

But when treated as an afterthought, everything downstream becomes reactive, and in MEP, reactive nearly always means expensive.

Don't risk costly errors. Get your HVAC shop drawings reviewed by our team of 200+ US-licensed MEP engineers who have delivered 500+ clash-free projects.